By Amanda Djäknegren

As a part of the course “PPU101 Form and manufacturing case studies” at Chalmers I performed a case study, where the goal was to take inspiration from the properties (both possibilities and restrictions) of polymeric materials when creating a product. Additionally, the product was supposed to fit into the PlayStation 5 product series and brand, and thus takes inspiration from the DualSense controller for the PS5. The concept of a new handheld console features a screwless design which takes advantage of the pliability of polymers. Prior to the development, a Design Format Analysis and Market Analysis was performed to understand the brand. The concept was developed using the Fish-trap model to create a wide variety of alternatives in a short period of time, and changes were made according to the Design Failure Mode and Effects Analysis which ensures potential design issues are fixed early in the process.

I chose to create a concept for a portable console taking inspiration from the features of the haptic DualSense controller, and the branding of PlayStation. It features a design where all screws are hidden, made possible by the slight flexibility of the polymer used for this product. Disassembly is done by first removing the black part of the handle which snaps in place, and then removing the screws underneath them. All parts are designed in such a way that all pieces have a draft angle to them, and no parts overlap themselves. This leads to the pieces being able to be molded with no parting lines of the mold being visible on the final product.

Acrylonitrile styrene acrylate (ASA) was chosen as a material since it has similar properties to ABS which was initially considered. Advantages to ASA includes its increased UV stability compared to ABS which prevents it from yellowing over time which may help it during aging and increases its longevity.

Process

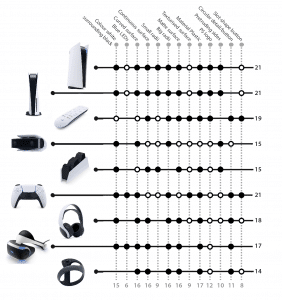

The brand and series of products I chose to work with was Sony’s Playstation 5 series of products since I find them to have a unique and interesting design language. The design language was explored using a Design Format Analysis in order to understand the products part of the Playstation 5 lineup – which features are the most important in creating a product that looks like a product from the fifth generation PlayStation series of products, and also which products are the most identifiable as PlayStation products.

A disassembly study and a market analysis of controllers and portable consoles was also performed. The purpose of the disassembly study was to understand the components which makes up a controller, while the purpose of the market analysis was to understand trends, advantages and disadvantages of the form of the consoles and controllers already on the market.

In order to generate a large number of alternatives in a short amount of time, the Fish-trap model as described by Muller (2001) was used. Topological variants were based on the basic structure of a screen and two handles. In order to aid with ergonomics, the handles were made a lot bigger than classical portable consoles but still smaller than the DualSense controller for the PS5, in order to keep the console portable. The structural concepts that were chosen had handles angled outwards which allows for better support for the hand and palm. The morphological step included multiple iterations of details where the Design Format Analysis proved to be a great guideline in how to express the essence of PlayStation.

The morphological step was scrutinised using a Design Failure Mode and Effects Analysis (DFMEA) which is a method where you analyse the parts of the design individually, as well as in relation to the other parts of the assembly. This is a powerful tool which makes it easier to spot flaws in design early in the design process. A number of changes were made based on the findings of this analysis.

The final concept was modelled using Fusion 360.