By Amanda Djäknegren

As a part of the course “PPU101 Form and manufacturing case studies” at Chalmers I performed a case study, where the goal was to take inspiration from the properties (both possibilities and restrictions) of metals when creating a bicycle basket. Additionally, the product was supposed to fit into the PlayStation 5 product series and brand. The bicycle basket has the form factor of a grocery bag and was created with sturdiness, lightness and durability in mind. In order to reduce the weight of the product, a pattern was created which is punched out of the sides, reducing the weight by 54%. Prior to the development, a Competitor Analysis and Design Format Analysis was performed to understand the brand. The concept was developed using the Fish-trap model to create a wide variety of alternatives in a short period of time, and changes were made according to the Design Failure Mode and Effects Analysis which ensures potential design issues are fixed early in the process.

The final design has the distinct colour scheme of white surrounding black similar to that of the Playstation 5. The blue colour of the LED’s on the Playstation was included as an accent on the handle of the basket. The design features a white clip-on solution that attaches to the bike rack semi-permanently and screws into itself. The basket can then be clipped on and off at will by its attachment points, and lifted up using the handle.

Stainless steel type 304 was chosen as the material of the product due to its high strength and low price compared to aluminium for example. The main features that were looked upon when choosing the grade of stainless steel was corrosion resistance and how well it can be welded.

Having a continuous surface is normally one of the most distinguishing features of a product in the PlayStation 5 product series, however, a continuous surface on this basket made out of metal would inherently make it very heavy. Therefore, a pattern was created, seen in the figure. The black parts of the pattern represents areas that are to be punched out during the making of the product, creating a 54% reduction in weight. Due to the shape of the pattern, a structurally strong surface is created at 46% of the weight. This is also good for the environment since less material is used for the product – the parts that are punched out can be melted and put back into production.

Process

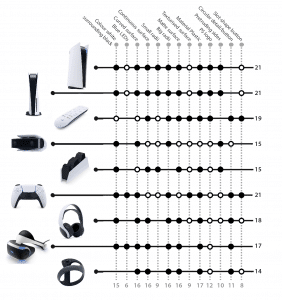

The brand and series of products I chose to work with was Sony’s Playstation 5 series of products since I find them to have a unique and interesting design language. The design language was explored using a Design Format Analysis in order to understand the products part of the Playstation 5 lineup – which features are the most important in creating a product that looks like a product from the fifth generation PlayStation series of products, and also which products are the most identifiable as PlayStation products.

The Fishtrap model was used in order to generate a large number of alternatives in a short amount of time, the Fishtrap model was used. The basic structures used in the topological variants were a bike and a rectangle which represents the general shape of the bicycle basket, drawn to scale of a grocery bag. This step proved to be very valuable since it helped in understanding where this rather big bicycle basket could fit on the bike.

Several typological variants were explored for the rear placement of the bike basket. In order to follow the guidelines of the Design Format Analysis, a design similar to the cuboid of the PS5 was envisioned with white surrounding black in the center, and a combination between large and small rounded edges.

The morphological step was conducted in Fusion 360 where the formal concept first was created and then modified in an iterative fashion in order to create the material concept.

A Design Failure Mode and Effect Analysis, or DFMEA for short, was performed. The DFMEA’s main purpose is to assist in finding issues with the design early in the process which can be fixed before any commitments to the design are made. In this case, adjustments were made to fade out the pattern on the side of the black part, which makes welding easier and also prevents any visual or structural defects in production. A coating was also chosen that resist wear over time.

Thank you to Dan Făcăeru for letting me use their 3D-modelled bicycle to allow for the bicycle basket to be put in its context.